Home > Stainless Steel > Stainless Steel 904L Heat Exchanger Tubing

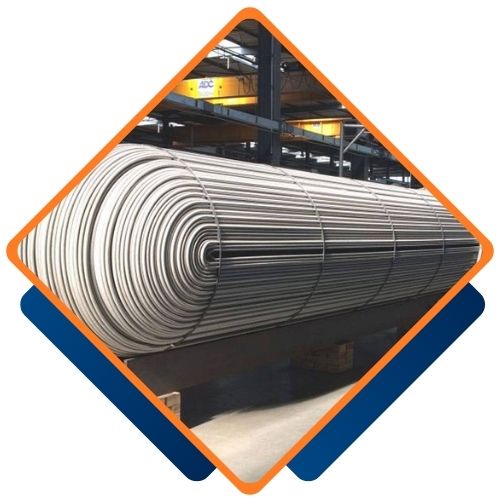

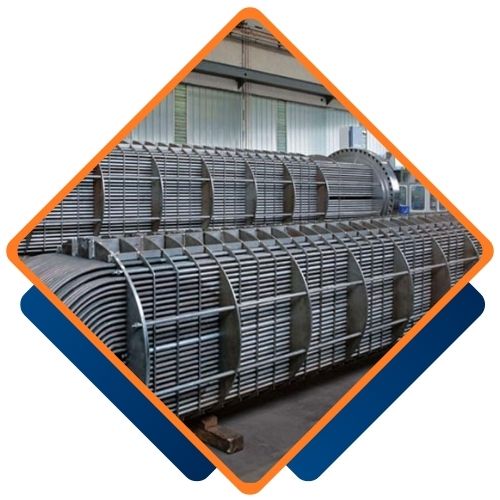

Ojas Pipes and Tubes, a prominent manufacturer and supplier based in Kolkata, India, is dedicated to providing top-notch Stainless Steel 904L Heat Exchanger Tubing for a variety of industrial uses. Renowned for its exceptional quality, resistance to corrosion, and long-lasting durability, these tubes are designed to meet the stringent requirements of sectors such as chemical processing, marine, power generation, and pharmaceuticals. Ojas guarantees that all products comply with international standards through meticulous manufacturing processes and rigorous quality control. With a strong reputation for excellence, prompt delivery, and a customer-centric approach, Ojas Pipes and Tubes has established itself as a reliable name in stainless steel heat exchanger solutions.

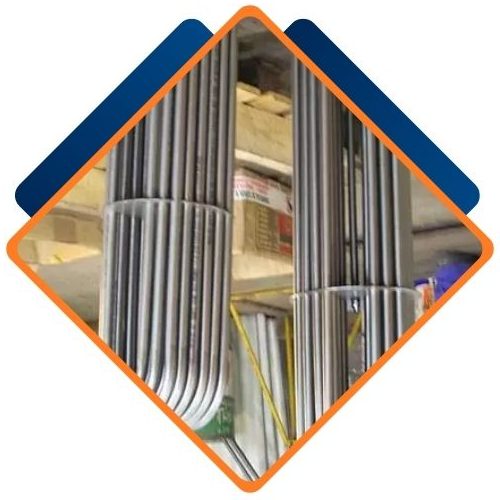

Stainless Steel 904L Heat Exchanger Tubing is an austenitic alloy containing approximately 19–23% chromium, 23–28% nickel, 4–5% molybdenum, and 1–2% copper, with a low carbon content that enhances its corrosion resistance. It boasts remarkable resistance to sulfuric, phosphoric, and acetic acids, making it exceptionally durable in challenging chemical environments. The tubing features a tensile strength of around 490 MPa, yield strength of about 220 MPa, and an elongation of roughly 35%. Its mechanical strength, coupled with excellent weldability and toughness, makes it perfect for demanding heat transfer applications under varying temperature and pressure conditions.

Range : 10 mm OD to 50.8 mm OD

Outer Diameter : 6.00 mm to 101.60 mm

Wall Thickness : 0.70 mm to 8.00 mm

Length : up to 20 m (65.62 ft) Length & Customed Required Length

Specifications : ASTM A 213, A 268, A 269, A 789, Equivalent to ASME, EN, JIS Etc.

| Element | SS 904L |

| C | 0.020 max |

| Mn | 2.00 max |

| Si | 1.00 max |

| P | 0.040 max |

| S | 0.030 max |

| Cr | 19.00 – 23.00 |

| Mo | 4.00 – 5.00 max |

| Ni | 23.00 – 28.00 |

| Cu | 1.00 – 2.00 |

| Element | SS 347 | SS 347H |

| Density | 8.0 g/cm3 | 8.0 g/cm3 |

| Melting Point | 1454 °C (2650 °F) | 1454 °C (2650 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 | Psi – 30000 , MPa – 205 |

| Elongation | 35 % | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 904L heat exchanger tubing from Ojas Pipes and Tubes ensures high-quality and reliable performance for your industrial applications. Our tubing is crafted from premium-grade 904L alloy, providing exceptional resistance to corrosion and pitting, making it ideal for harsh environments. With our commitment to precision manufacturing and stringent quality control, you can trust that our products meet international standards. Additionally, our experienced team offers personalized service, timely delivery, and expert guidance, ensuring you find the right solution for your specific needs. Choose Ojas Pipes and Tubes for superior quality and performance.

Ojas Pipes and Tubes, one of the largest suppliers of Stainless Steel 904L Heat Exchanger Tubing in Kolkata, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel 904L Heat Exchanger Tubing to meet your specific requirements. Our team at Ojas Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@ojaspipesandtubes.co.in.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z6CNDT17‐123 | X1NiCrMoCu25-20-5 |

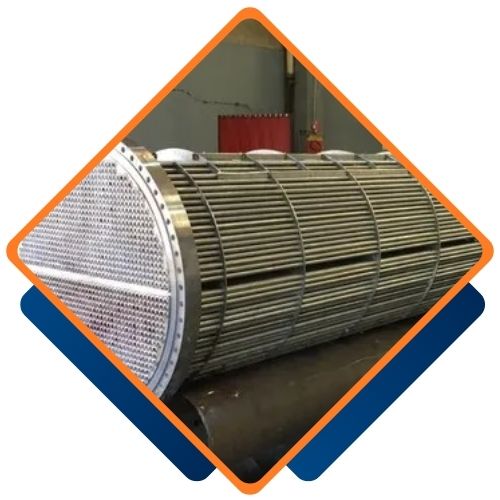

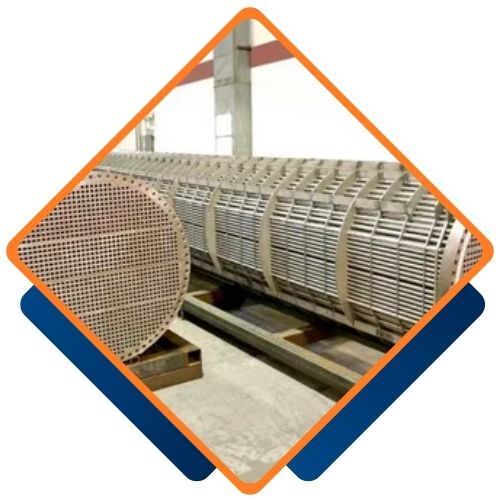

Stainless Steel 904L Heat Exchanger Tubing is widely utilized in industries where effective heat transfer and corrosion resistance are essential. Typical applications include chemical process equipment, pharmaceutical heat exchangers, marine condensers, power plant coolers, and food processing facilities. The tubing’s ability to withstand pitting, crevice corrosion, and stress corrosion cracking ensures a long service life even in harsh, corrosive settings. Its outstanding thermal conductivity and strength make it suitable for both shell-and-tube and plate-type heat exchangers, delivering reliable performance across high-temperature and high-pressure environments.

©2024 Ojas Pipes and Tubes . All Rights Reserved.