Home > Stainless Steel > Stainless Steel 321/321H Seamless Tubing

Ojas Pipes and Tubes, a reputable manufacturer and supplier based in Kolkata, India, specializes in high-quality Stainless Steel 321/321H Seamless Tubing tailored to meet the toughest industrial demands. With a keen emphasis on precision, durability, and top-notch quality, Ojas provides tubing solutions that excel in high-temperature and corrosive settings. The Stainless Steel 321/321H, which is stabilized with titanium, boasts exceptional resistance to intergranular corrosion and stress cracking, making it perfect for aerospace, chemical, and thermal applications. Ojas Pipes and Tubes is recognized for its dedication to international standards, prompt delivery, and customer satisfaction, establishing itself as a go-to partner across various industries.

Stainless Steel 321/321H Seamless Tubing consists of iron, 17-19% chromium, 9-12% nickel, and up to 1% titanium, which enhances its resistance to high-temperature oxidation. The mechanical properties include a tensile strength of approximately 515 MPa and a yield strength of around 205 MPa, ensuring excellent durability. The advantages of 321/321H tubing include superior resistance to intergranular corrosion, making it suitable for elevated temperatures. Its titanium addition prevents carbide precipitation, ensuring stability in high-temperature applications. This tubing is ideal for use in chemical processing, aerospace, and petrochemical industries.

Tube Range : 6.35 mm OD To 101.6 mm OD Guage: 25 SWG – 10 SWG

Outer Diameter : 3.00 mm – 219.10 mm

Wall Thickness : 0.40 mm – 12.70 mm

Schedules : 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH

Length : Upto 30 meters, Custom Cut Lengths

Specifications : ASTM A213 / ASTM SA213

Types : Round, Square, Rectangle, Coil, “U” Shape, Hydraulic & Honed Tubes

| SS | 321 | 321H |

| Ni | 09 – 12 | 09 – 12 |

| N | 0.10 | 0.10 |

| Cr | 17 – 19 | 17 – 19 |

| C | 0.08 max | 0.04 – 0.08 |

| Si | 1 max | 0.75 max |

| Mn | 2 max | 2 max |

| P | 0.040 max | 0.045 max |

| S | 0.030 max | 0.03 max |

| TI | 4(C+N) | 0.70 max |

| Grade | 321 | 321H |

| Tensile Strength (MPa) min | 515 | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 | 205 |

| Elongation (% in 50mm) min | 40 | 40 |

| Hardness | ||

| Rockwell B (HR B) max | 95 | 95 |

| Brinell (HB) max | 217 | 217 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Stainless Steel 321/321H Seamless Tubing is composed of approximately 17–19% chromium, 9–12% nickel, titanium (which is about five times the carbon content), and low carbon in 321 or a higher carbon content (around 0.04–0.10%) in 321H to enhance high-temperature strength. It features a tensile strength of about 515 MPa, a yield strength of around 205 MPa, and an elongation of roughly 40%. These tubes exhibit excellent resistance to creep, stress rupture, and oxidation at temperatures reaching up to 900°C. The titanium stabilization helps reduce carbide precipitation, ensuring remarkable corrosion resistance, especially in applications that involve repeated heating and cooling cycles.

Ojas Pipes and Tubes, one of the largest suppliers of Stainless Steel 321/321H Seamless Tubing in Kolkata, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel 321/321H Seamless Tubing to meet your specific requirements. Our team at Ojas Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@ojaspipesandtubes.co.in.

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 321 | S32100 | 321S31 | 58B, 58C | 1.4541 | X6CrNiTi18-10 | 2337 | SUS 321 |

| 321H | S32109 | 321S51 | – | 1.4878 | X6CrNiTi18-10 | – | SUS 321H |

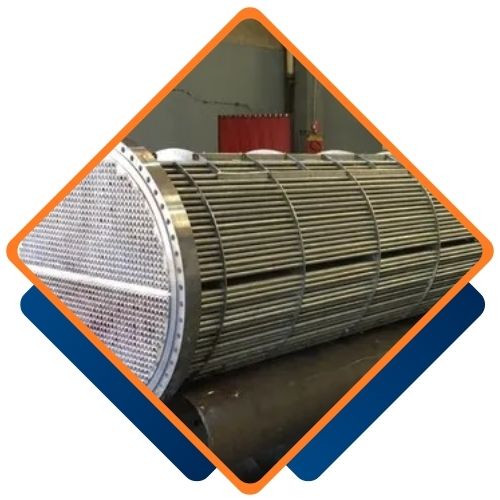

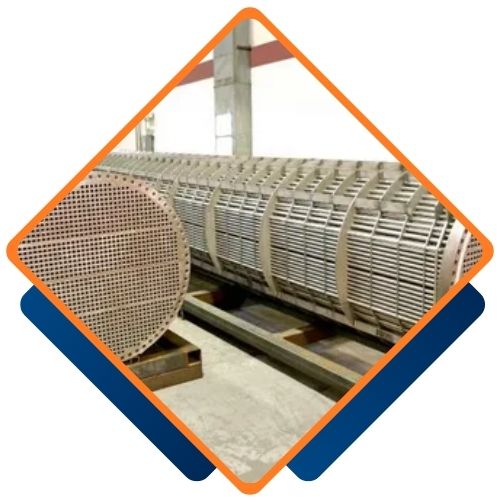

Stainless Steel 321/321H Seamless Tubing is extensively utilized in scenarios that require high-temperature strength along with outstanding resistance to corrosion and oxidation. It’s perfect for heat exchangers, furnace components, chemical processing equipment, aerospace exhaust systems, thermal oxidizers, and high-temperature pressure vessels. Industries such as petrochemical, aerospace, oil & gas, and refineries depend on 321/321H tubing for its reliable performance under thermal cycling and elevated temperatures. The increased carbon content in 321H provides additional creep strength, making it especially suitable for continuous operation at high temperatures.

©2024 Ojas Pipes and Tubes . All Rights Reserved.