Home > Stainless Steel > Stainless Steel 317 and 317L ERW Pipes

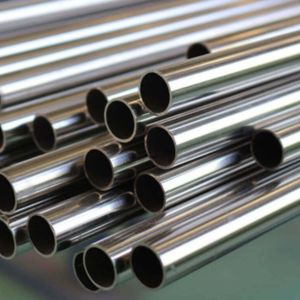

Ojas Pipes and Tubes stands out as a trusted manufacturer and supplier of Stainless Steel 317 and 317L ERW Pipes in Kolkata, India. We specialize in delivering top-notch welded piping solutions designed for corrosive and high-temperature settings. SS 317 and 317L are austenitic stainless steels enriched with molybdenum, which gives them exceptional resistance to pitting and crevice corrosion. Our ERW (Electric Resistance Welded) pipes are crafted in line with international standards like ASTM A312 and ASTM A269, ensuring they boast excellent dimensional accuracy and weld integrity. Perfect for chemical processing, pharmaceuticals, and marine applications, Ojas guarantees pipes that consistently deliver quality and reliable performance.

SS 317 and 317L ERW Pipes are composed of Chromium (18–20%), Nickel (11–15%), and a higher Molybdenum content (3–4%), which significantly boosts their corrosion resistance in chloride-heavy environments. The carbon content is kept to ≤0.08% in 317 and ≤0.03% in 317L, enhancing weldability and minimizing carbide precipitation. These pipes exhibit impressive mechanical properties, with a tensile strength ranging from 515 to 750 MPa, yield strength between 205 and 275 MPa, and elongation of up to 40%. They maintain outstanding strength and corrosion resistance even at elevated temperatures, making them perfect for demanding industrial and marine conditions.

Specifications : ASTM A312 / ASME SA312

Dimensions : ASTM, ASME and API

Size : 8″ NB to 24″ NB

Wall Thickness : 0.5 to 150mm Thick

Schedules : SCH 5S, 10S,10, 20, 40S, 40, STD, 60, 80S, 80, XS, 100, 120, 140, 160 & XXS

Length : Single Random, Double Random & Required Length

Form : Round, Square, Rectangular, Hydraulic Pipes

End : Plain end, Bevelled end

Type : Electric Resistance Welded

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 317 and 317L ERW Pipes from Ojas Pipes and Tubes guarantees excellent corrosion resistance, high strength, and durability. Designed for diverse industrial applications, it delivers reliable performance in tough environments while maintaining competitive pricing for cost-effective solutions.

Ojas Pipes and Tubes, a leading manufacturer and supplier of Stainless Steel 317 and 317L ERW Pipes in Kolkata, India, offers a comprehensive range of high-quality pipes and tubing suitable for various industrial applications. Our extensive inventory and commitment to exceptional service make us a trusted choice for regional products.

| STANDARD | UNS | WERKSTOFF NR. | EN | JIS |

| SS 317 | S31700 | 1.4449 | – | SUS 317 |

| SS 317L | S31703 | 1.4438 | X2CrNiMo18-15-4 | SUS 31 |

We offer custom sizes for Stainless Steel 317 and 317L ERW Pipes to meet your specific needs. Our dedicated team at Ojas Pipes and Tubes provides tailored solutions for all your piping and tubing requirements. For more information, contact us at sales@ojaspipesandtubes.co.in.

Stainless Steel 317 and 317L ERW Pipes find extensive use across various sectors, including chemical and petrochemical industries, pharmaceutical processing, food and beverage manufacturing, and marine applications. Their superior resistance to pitting and crevice corrosion makes them ideal for heat exchangers, pressure vessels, and piping systems that handle acids, chlorides, and saltwater. Additionally, these pipes are utilized in water treatment facilities, the paper and pulp industry, and wastewater treatment processes. The ERW manufacturing technique guarantees consistent welds and precise dimensions, making them essential for applications where strength, corrosion resistance, and durability are crucial.

©2024 Ojas Pipes and Tubes . All Rights Reserved.