Home > Stainless Steel > Stainless Steel 316Ti Seamless Tubing

Ojas Pipes and Tubes, a well-respected manufacturer and supplier located in Kolkata, India, specializes in providing high-quality Stainless Steel 316Ti Seamless Tubing for demanding industrial applications. Renowned for their precision engineering and commitment to superior quality, Ojas ensures that their seamless tubing meets international standards, offering exceptional corrosion resistance and high-temperature performance. The Stainless Steel 316Ti grade is titanium-stabilized, making it resistant to intergranular corrosion even after welding or exposure to high heat. With a strong focus on customer satisfaction, timely delivery, and competitive pricing, Ojas has earned a solid reputation as a reliable partner in the stainless steel tubing sector.

Stainless Steel 316Ti Seamless Tubing is composed of approximately 16–18% chromium, 10–14% nickel, 2–3% molybdenum, and a controlled amount of titanium (at least five times the carbon content) to enhance its resistance to sensitization. It boasts a tensile strength of around 515 MPa, a yield strength of about 205 MPa, and an elongation of roughly 35–40%. This tubing maintains its mechanical integrity at high temperatures and offers excellent resistance to pitting, crevice corrosion, and general corrosion in chloride environments. Additionally, it provides great toughness, good formability, and outstanding weldability, making it perfect for precision and heavy-duty industrial applications.

Tube Range : 6.35 mm OD To 101.6 mm OD Guage: 25 SWG – 10 SWG

Outer Diameter : 3.00 mm – 219.10 mm

Wall Thickness : 0.40 mm – 12.70 mm

Schedules : 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH

Length : Upto 30 meters, Custom Cut Lengths

Specifications : ASTM A269 / ASTM SA269

Types : Round, Square, Rectangle, Coil, “U” Shape, Hydraulic & Honed Tubes

| SS | 316TI |

| Ni | 10 – 14 |

| N | 0.10 max |

| Cr | 16 – 18 |

| C | 0.08 max |

| Si | 0.75 max |

| Mn | 2 max |

| P | 0.045 max |

| S | 0.030 max |

| Mo | 2.00 – 3.00 |

| Grade | 316TI |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 35 |

| Hardness | |

| Rockwell B (HR B) max | 75 |

| Brinell (HB) max | 205 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 316Ti Seamless Tubing from Ojas Pipes and Tubes ensures you receive a product with exceptional quality and reliability. Our 316Ti tubing, enhanced with titanium for superior high-temperature strength and corrosion resistance, is ideal for demanding applications such as chemical processing, power generation, and marine environments. We prioritize customer satisfaction by offering customized solutions, rigorous quality control, and precision manufacturing to meet your specific requirements. With our industry expertise and commitment to excellence, Ojas Pipes and Tubes delivers seamless tubing that stands the test of time in even the most challenging conditions.

Ojas Pipes and Tubes, one of the largest suppliers of Stainless Steel 316Ti Seamless Tubing in Kolkata, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel 316Ti Seamless Tubing to meet your specific requirements. Our team at Ojas Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@ojaspipesandtubes.co.in.

| Specific Heat (0-100°C) | Thermal Conductivity | Thermal Expansion | Modulus Elasticity | Electrical Resistivity | Density |

| 500 | 14.6 | 16.5 | 193 | 7.4 | 7.99 |

| J.kg-1.°K-1 | W.m -1.°K-1 | mm/m/°C | GPa | μohm/cm | g/cm3 |

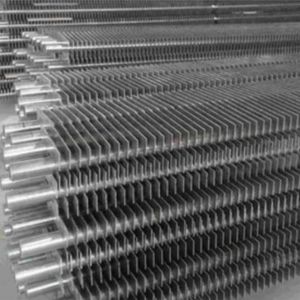

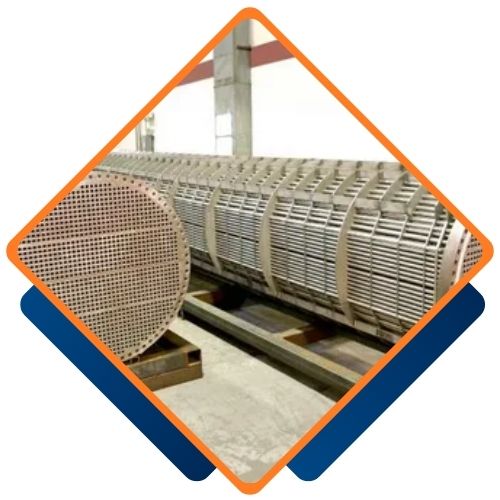

Stainless Steel 316Ti Seamless Tubing is extensively utilized in various industries that demand exceptional corrosion resistance and high-temperature performance. Common applications include chemical processing plants, power generation systems, pharmaceutical manufacturing, food processing equipment, heat exchangers, condensers, and marine components. Thanks to its titanium stabilization, this tubing is particularly well-suited for welded structures and systems that face harsh environments, such as those with acidic or chloride-containing media. It is also employed in automotive exhaust systems, aerospace applications, and instrumentation, showcasing its versatility and reliability across multiple sectors.

©2024 Ojas Pipes and Tubes . All Rights Reserved.