Home > Stainless Steel > Stainless Steel 316H Electropolished Pipes

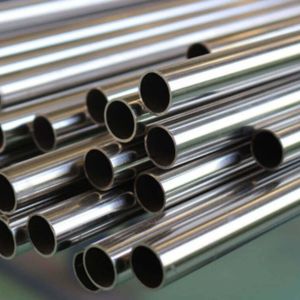

Many industries that require high performance in challenging conditions and robust corrosion resistance use stainless steel 316 tubing. It is frequently used in medical equipment, food and beverage production, pharmaceutical manufacturing, marine applications, and chemical and petrochemical processing. Heat exchangers, fluid transfer systems, pressure vessels, and hydraulic lines are all excellent applications for SS 316 tubing. It is appropriate for both offshore and coastal projects due to its resistance to harsh temperatures, acidic chemicals, and saltwater. SS 316 is also favoured in sanitary applications like clean rooms, biotech labs, and dairy processing systems due to its exceptional weldability and hygienic qualities.

High-carbon versions of stainless steel 316, known as 316H electropolished pipes, are made to be stronger at higher temperatures. In addition to manganese, silicon, phosphorus, and sulphur in trace amounts, their composition consists of chromium (16–18%), nickel (10–14%), molybdenum (2–3%), and carbon (0.04–0.10%). These pipes have a minimum yield strength of 30,000 psi (205 MPa) and tensile strength of 75,000 psi (515 MPa). They are perfect for high-purity and high-temperature applications that require exceptional mechanical and chemical performance because the electropolishing process improves surface smoothness, corrosion resistance, and cleanliness.

| Electropolished Pipe Standard | ASTM A269 / ASME SA269 |

| Electropolished Pipe Dimension | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Seamless Electropolished Pipe Sizes | 1 / 2″ NB – 16″ NB |

| Welded Electropolished Pipe Sizes | 1 / 2″ NB – 24″ NB |

| Electropolished Pipe Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Electropolished Pipes available Ex-stock |

| Electropolished Pipe Manufacturing Process | Seamless / Welded / ERW / Fabricated / CDW / 100% X Ray Welded |

| Stainless Steel Electropolished Pipe Schedule | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Electropolished Pipe Length | Single Random, Double Random, Standard & Cut length |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Outside Finish | 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Electropolished Pipes, Finish as per customer Requirements |

| Value Added Services | Cutting, Beveling, Polishing, Threading, Destructive, Non Destructive, Ultrasonic Testing |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Ojas Pipes and Tubes, a leading manufacturer and supplier of Stainless Steel 316H Electropolished Pipes in Kolkata, India, offers a comprehensive range of high-quality pipes and tubing suitable for various industrial applications. Our extensive inventory and commitment to exceptional service make us a trusted choice for regional products.

| STANDARD | WERKSTOFF NR. | UNS |

| SS 316H | 1.4919 | S31609 |

We offer custom sizes for Stainless Steel 316H Electropolished Pipes to meet your specific needs. Our dedicated team at Ojas Pipes and Tubes provides tailored solutions for all your piping and tubing requirements. For more information, contact us at sales@ojaspipesandtubes.co.in.

In industries where corrosion resistance, strength, and surface finish are crucial, stainless steel 316H electropolished pipes are widely used. Cleanroom installations, food and beverage systems, biotech procedures, and pharmaceutical manufacturing are examples of common applications. Because of their high carbon content and ability to retain strength at high temperatures, these pipes are also perfect for high-temperature applications like pressure vessels, boilers, and heat exchangers. By reducing surface roughness, the electropolished finish ensures easy cleaning and stops microbial contamination. For systems needing extremely smooth, sanitary, and long-lasting piping solutions under harsh operating conditions, SS 316H EP pipes are the recommended option.

©2024 Ojas Pipes and Tubes . All Rights Reserved.