Home > Stainless Steel > Stainless Steel 316 Tubing

Because of its exceptional resistance to oxidation, corrosion, and thermal fatigue, stainless steel 310 tubing is frequently utilised in high-temperature and high-stress applications. It is perfect for kiln liners, radiant tubes, heat exchangers, and furnace parts. Additionally, cement plants, thermal oxidisers, power generation, and petrochemical processing all use SS 310 tubing. It is appropriate for incinerators and combustion chambers due to its structural stability under thermal cycling. Long service life in environments with sulphur, carburising gases, or other aggressive media is also made possible by its weldability and high chromium-nickel content. For demanding industrial operations, it is a dependable solution.

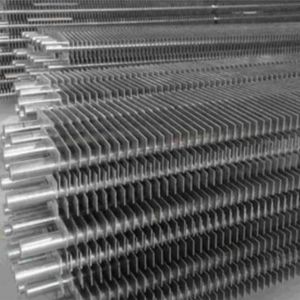

Stainless Steel 316 Tubing is composed of chromium (16-18%), nickel (10-14%), and molybdenum (2-3%) with traces of carbon and manganese, silicon and phosphorus. It offers excellent mechanical properties with a tensile strength of 515 MPa yield strength of 205 MPa and elongation of 40%. The addition of molybdenum enhances its corrosion resistance especially against chlorides and acids. Key advantages include exceptional resistance to pitting and crevice corrosion high-temperature strength and excellent weldability. These properties make it ideal for marine as well as chemical and pharmaceutical applications ensuring longevity and reliability in demanding environments.

| Tube Range | 6.35 mm OD To 101.6 mm OD Guage: 25 SWG – 10 SWG |

| Outer Diameter | 3.00 mm – 219.10 mm |

| Wall Thickness | 0.40 mm – 12.70 mm |

| Schedules | 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH |

| Length | Upto 30 meters, Custom Cut Lengths |

| Specifications | ASTM A213 / ASTM SA213 |

| Types | Round, Square, Rectangle, Coil, “U” Shape, Hydraulic & Honed Tubes |

| STANDARD | UNS | WERKSTOFF NR. | JIS | AFNOR | BS | GOST | EN |

| SS 316 | S31600 | 1.4401 / 1.4436 | SUS 316 | Z7CND17‐11‐02 | 316S31 / 316S33 | – | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS | 316 |

| Ni | 10 – 14 |

| N | 0.10 max |

| Cr | 16 – 18 |

| C | 0.08 max |

| Si | 0.75 max |

| Mn | 2 max |

| P | 0.045 max |

| S | 0.030 max |

| Mo | 2.00 – 3.00 |

| Grade | 316 |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 40 |

| Hardness | |

| Rockwell B (HR B) max | 95 |

| Brinell (HB) max | 217 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 316 Tubing from Ojas Pipes and Tubes ensures high quality and durability, as these tubing offer excellent corrosion resistance and strength. Our commitment to exceptional service and reliable delivery guarantees customer satisfaction across various industrial applications. Our expertise in stainless steel products ensures you receive a top-tier solution tailored to your needs.

Ojas Pipes and Tubes, one of the largest suppliers of Stainless Steel 316 Tubing in Kolkata, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 316 | S31600 | 316S31 | 58H, 58J | 1.4401 | X5CrNiMo17-12-2 | 2347 | SUS 316 |

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

| 0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C | |||||

| 316 | 8000 | 193 | 15.9 | 16.2 | 17.5 | 16.3 | 21.5 | 500 | 740 |

Yes, we offer custom sizes for Stainless Steel 316 Tubing to meet your specific requirements. Our team at Ojas Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@ojaspipesandtubes.co.in.

Many industries that require high performance in challenging conditions and robust corrosion resistance use stainless steel 316 tubing. It is frequently used in medical equipment, food and beverage production, pharmaceutical manufacturing, marine applications, and chemical and petrochemical processing. Heat exchangers, fluid transfer systems, pressure vessels, and hydraulic lines are all excellent applications for SS 316 tubing. It is appropriate for both offshore and coastal projects due to its resistance to harsh temperatures, acidic chemicals, and saltwater. SS 316 is also favoured in sanitary applications like clean rooms, biotech labs, and dairy processing systems due to its exceptional weldability and hygienic qualities.

©2024 Ojas Pipes and Tubes . All Rights Reserved.