Home > Stainless Steel > Stainless Steel 316/316L Heat Exchanger Tubing

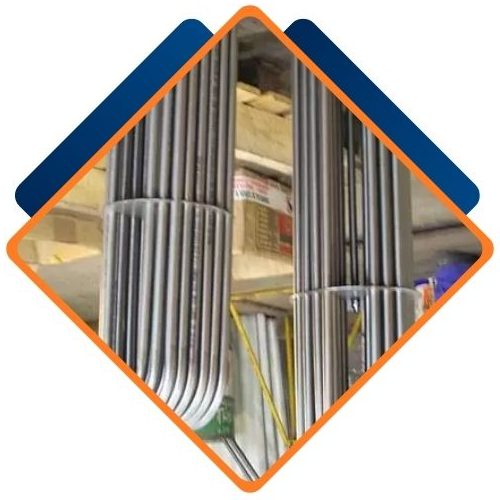

Ojas Pipes and Tubes is a well-established manufacturer and supplier in Kolkata, India, dedicated to producing high-quality Stainless Steel 316/316L Heat Exchanger Tubing. Distinguished by quality and dependability, Ojas provides corrosion-resistant and high-performance tubing solutions customized for critical industrial uses. By focusing on precision engineering and international standard adherence, the company ensures that every tube is up to the highest standards of durability and efficiency. Ojas Pipes and Tubes has a wide customer base throughout India and abroad, offering specialized solutions to industries such as chemical processing, power generation, and shipping industries.

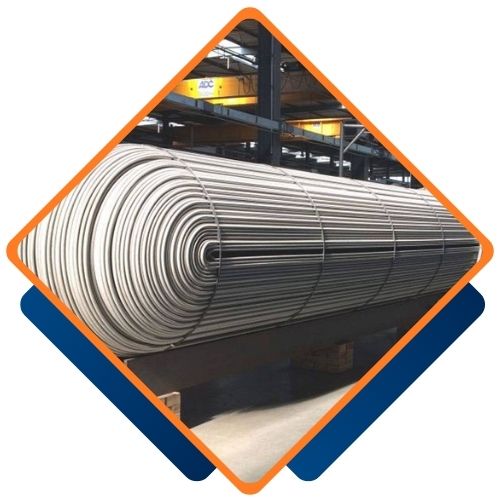

Stainless Steel 316/316L consists mainly of 16–18% Chromium, 10–14% Nickel, and 2–3% Molybdenum, with minimal carbon levels in 316L for superior weldability. It possesses superb resistance to corrosion, particularly in chloride and acidic conditions. The product has a tensile strength of 515 MPa, yield strength of 205 MPa, and an elongation of 40%. Renowned for its strength, it retains mechanical stability at both high and low temperatures, qualifying it for use in heat exchanger plants under chemically aggressive and thermally harsh environments.

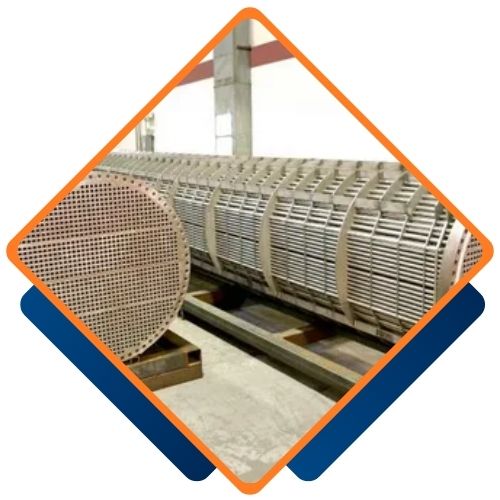

Range : 10 mm OD to 50.8 mm OD

Outer Diameter : 6.00 mm to 101.60 mm

Wall Thickness : 0.70 mm to 8.00 mm

Length : up to 20 m (65.62 ft) Length & Customed Required Length

Specifications : ASTM A 213, A 268, A 269, A 789, Equivalent to ASME, EN, JIS Etc.

| Element | SS 316 | SS 316L |

| C | 0.08 max | 0.035 max |

| Mn | 2.0 max | 2.0 max |

| Si | 1.0 max | 1.0 max |

| P | 0.045 max | 0.045 max |

| S | 0.030 max | 0.030 max |

| Cr | 16.00 – 18.00 | 16.00 – 18.00 |

| Mo | 2.00 – 3.00 | 2.00 – 3.00 |

| Ni | 11.00 – 14.00 | 10.00 – 14.00 |

| Fe | 67.845 min | 68.89 min |

| Element | SS 316 | SS 316L |

| Density | 8.0 g/cm3 | 8.0 g/cm3 |

| Melting Point | 1400 °C (2550 °F) | 1399 °C (2550 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 | Psi – 30000 , MPa – 205 |

| Elongation | 35 % | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 316/316L Heat Exchanger Tubing from Ojas Pipes and Tubes ensures access to high-quality materials tailored for durability and performance. With a commitment to excellence, Brydon offers precise dimensions and superior corrosion resistance, making their tubing ideal for challenging environments. The company’s expertise in manufacturing guarantees reliability and compliance with industry standards. Additionally, Brydon’s dedicated customer service provides personalized support, ensuring clients find the right solutions for their specific needs. Trust Ojas Pipes and Tubes for unparalleled quality and performance in stainless steel heat exchanger tubing.

Ojas Pipes and Tubes, one of the largest suppliers of Stainless Steel 316/316L Heat Exchanger Tubing in Kolkata, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel 316/316L Heat Exchanger Tubing to meet your specific requirements. Our team at Ojas Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@ojaspipesandtubes.co.in.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

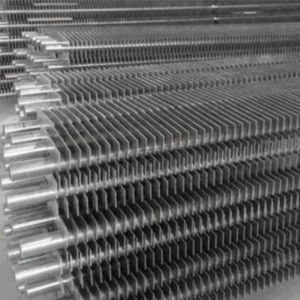

Stainless Steel 316/316L Heat Exchanger Tubing finds extensive application in industries where there is a high need for corrosion resistance and heat conductivity. Its main applications are chemical and petrochemical processing, power generation, pharmaceutical manufacture, and marine environments. The tubing is well suited for heat exchangers, condensers, evaporators, and boilers where it can transfer heat efficiently while withstanding corrosion by aggressive fluids like seawater, acids, and chlorides. Its low carbon variant, 316L, is particularly useful in welded systems that need resistance to intergranular corrosion. Ojas Pipes and Tubes ensures that every tube functions reliably in these demanding applications.

©2024 Ojas Pipes and Tubes . All Rights Reserved.