Home > Stainless Steel > Stainless Steel 304L Heat Exchanger Tubing

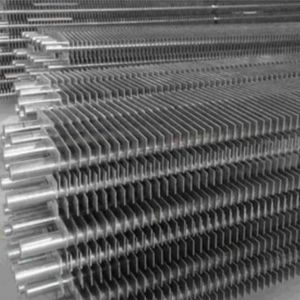

Ojas Pipes and Tubes is a renowned stainless steel tubing solutions manufacturer and supplier from Kolkata, India. Its area of expertise includes Stainless Steel 304L Heat Exchanger Tubing, which makes it known for its precision engineering, high material quality, and customer satisfaction. Ojas Pipes and Tubes supplies tubing solutions to varied industries with corrosion-resistant, long-lasting, and high-performance tubing, which is suitable for high-thermal-demand applications. With robust distribution channels and seasoned staff, Ojas facilitates on-time delivery and superior product quality, becoming a go-to partner for heat exchanger tubing solutions in India and global markets.

Stainless Steel 304L Heat Exchanger Tubing consists mainly of chromium (18–20%), nickel (8–12%), and a maximum of 0.03% carbon for better weldability and resistance to corrosion. It is also consisted of manganese, silicon, phosphorus, sulfur, and the balance iron. Mechanically, it has a minimum tensile strength of 485 MPa, yield strength of more than 170 MPa, and elongation of about 35%. Having a Brinell hardness of less than 201 HB, this grade has very good formability and strength with structural stability at high-stress and high-temperature conditions, which is very important for heat exchanger applications.

| Standard | ASTM A249/ ASME SA 249, ASTM A269/ ASME SA 269, ASTM A789/ ASME SA 789 |

| Wall Thickness Range | 0.5 To 5 mm |

| Delivery Condition | Annealed and Pickled, Bright Annealed, Polished, Cold Drawn, MF |

| Size Range | 6.53 to 127 mm |

| Length | up to 20 Meter |

| Bending radius | 1.25 x Outer Diameter up to 1700mm |

| Tolerance | +/-0.05 Mm |

| Processing Service | Cutting, Decoiling, Bending, Punching, Welding, Moulding |

| END | Plain End, Beveled End, Treaded |

| Technique | Hot rolled, Cold rolled, Cold drawn, Extrusion Tube |

| Grades | Phosphorus | Sulfur | Carbon | Chromium | Manganese | Silicon | Nickel |

|---|---|---|---|---|---|---|---|

| SS 304L | 0.045 | 0.03 | 0.08 | 18.0-20.0 | 2 | 1 | 8.0-11.0 |

| Material | Temperure | Tensile Properties | Yield Properties | Heat | Elongational |

|---|---|---|---|---|---|

| Min. º F(º C) | Ksi , Min. | Ksi , Min. | Treatment | ||

| SS 304L | 1900 (1040) | 75(515) | 30(205) | Solution | 35 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 304L Heat Exchanger Tubing from Ojas Pipes and Tubes ensures you receive high-quality products tailored to your industrial needs. Our tubing features excellent corrosion resistance and low carbon content, minimizing the risk of intergranular corrosion, making it ideal for harsh environments. We employ advanced manufacturing techniques and rigorous quality control to guarantee durability and reliability. Additionally, our commitment to customer service means we offer customized solutions, competitive pricing, and prompt delivery, establishing us as your trusted partner in the supply of heat exchanger tubing.

Ojas Pipes and Tubes, one of the largest suppliers of Stainless Steel Heat Exchanger Tubing in Kolkata, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel 304L Heat Exchanger Tubing to meet your specific requirements. Our team at Ojas Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@ojaspipesandtubes.co.in.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304L | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

Stainless Steel 304L Heat Exchanger Tubing is extensively employed in industries requiring high corrosion resistance and high-temperature thermal performance. It is applied in chemical processing plants, oil and gas refineries, food and beverage factories, and power generation facilities. The tubing is predominantly utilized in condensers, heat exchangers, evaporators, and boiler units, where it transfers heat effectively without degradation. Its low carbon content makes it suitable for welding and minimizes the possibility of intergranular corrosion, even following exposure to high temperatures. Its hygienic surface characteristics also make it fit for pharmaceutical and dairy processing industries.

©2024 Ojas Pipes and Tubes . All Rights Reserved.