Home > Stainless Steel > Stainless Steel 304H Heat Exchanger Tubing

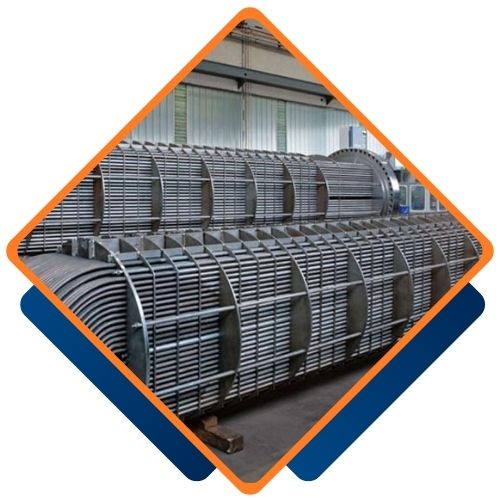

Ojas Pipes and Tubes is a top Kolkata, India-based manufacturer and supplier of high-end stainless steel tubing solutions. With a reputation for precision and reliability, Ojas provides Stainless Steel 304H Heat Exchanger Tubing that is built for the rigorous demands of industrial applications. Equipped with cutting–edge manufacturing facilities and rigorous quality checks, the company provides tubing on par with international standards. Their experience, sound service, and customer-oriented nature provide them as the preferred vendor among clients from industries of power generation, petrochemicals, and refineries for high-quality heat exchanger tubing solutions.

Stainless Steel 304H Heat Exchanger Tubing has high carbon levels (0.04–0.10%) to ensure improved high-temperature strength. It has a common composition of 18–20% Chromium and 8–11% Nickel to ensure high corrosion resistance. Its mechanical properties consist of a minimum tensile strength of 515 MPa, yield strength of 205 MPa, and elongation of 40%. Its melting point is approximately 1400°C, and it maintains strength at high temperatures, qualifying it for high-pressure and high-temperature conditions. Its structure provides dimensional stability and consistent performance in severe thermal applications.

| Standard | ASTM A249/ ASME SA 249, ASTM A269/ ASME SA 269, ASTM A789/ ASME SA 789 |

| Wall Thickness Range | 0.5 To 5 mm |

| Delivery Condition | Annealed and Pickled, Bright Annealed, Polished, Cold Drawn, MF |

| Size Range | 6.53 to 127 mm |

| Length | up to 20 Meter |

| Bending radius | 1.25 x Outer Diameter up to 1700mm |

| Tolerance | +/-0.05 Mm |

| Processing Service | Cutting, Decoiling, Bending, Punching, Welding, Moulding |

| END | Plain End, Beveled End, Treaded |

| Technique | Hot rolled, Cold rolled, Cold drawn, Extrusion Tube |

| Grades | Phosphorus | Sulfur | Carbon | Chromium | Manganese | Silicon | Nickel |

|---|---|---|---|---|---|---|---|

| SS 304H | 0.045 | 0.03 | 0.08 | 18.0-20.0 | 2 | 1 | 8.0-11.0 |

| Material | Temperure | Tensile Properties | Yield Properties | Heat | Elongational |

|---|---|---|---|---|---|

| Min. º F(º C) | Ksi , Min. | Ksi , Min. | Treatment | ||

| SS 304H | 1900 (1040) | 75(515) | 30(205) | Solution | 35 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 304H Heat Exchanger Tubing from Ojas Pipes and Tubes ensures exceptional quality and reliability. Our tubing is manufactured to stringent industry standards, providing superior corrosion resistance and high-temperature performance essential for demanding applications. With a focus on precision engineering, our products offer excellent durability and longevity, reducing maintenance costs over time. Additionally, our experienced team provides personalized support and expertise to meet your specific requirements, ensuring timely delivery and satisfaction. Trust Ojas Pipes and Tubes for high-performance solutions tailored to your needs.

Ojas Pipes and Tubes, one of the largest suppliers of Stainless Steel 304H Heat Exchanger Tubing in Kolkata, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel 304H Heat Exchanger Tubing to meet your specific requirements. Our team at Ojas Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@ojaspipesandtubes.co.in.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304H | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

Stainless Steel 304H Heat Exchanger Tubing finds extensive application in industries that require resistance to corrosion and high temperatures. Some of its main applications are in heat exchangers, condensers, boilers, and superheaters in power generation and refineries. It is also used in petrochemical and chemical industries for the transfer of fluids and cooling systems, due to its high mechanical properties and resistance to oxidizing agents. The stability of the tubing at higher temperatures makes it suitable for high-pressure systems. It is also used in marine systems, pulp and paper processing, and food processing systems where durability and cleanliness are important.

©2024 Ojas Pipes and Tubes . All Rights Reserved.