Home > Nickel Alloy > Nickel Alloy Instrumentation Tubing

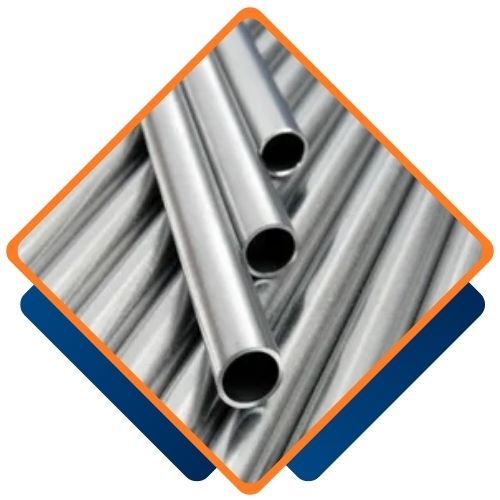

Based in Delhi, India, Ojas Pipes and Tubes is a reputable producer and supplier of high-performance nickel alloy instrumentation tubing. Ojas is well-known for providing precisely engineered tubing solutions that meet the demanding needs of the petrochemical, marine, oil and gas, and power generation industries. Because of its exceptional resistance to corrosion, pressure, and high temperatures, our nickel alloy instrumentation tubing is made for harsh conditions. Ojas is a preferred partner for critical instrumentation and control systems globally because of our advanced production capabilities and strong emphasis on quality assurance, which guarantee dependable performance, dimensional accuracy, and on-time delivery.

Instrumentation for Nickel Alloy Depending on the alloy type (e.g., Inconel, Monel, Hastelloy), tubing may contain elements like chromium, molybdenum, copper, and iron in addition to its primary component of high-purity nickel (up to 99% in some grades). These components enhance mechanical strength, oxidation resistance, and corrosion resistance. Excellent yield strength and tensile strength between 75,000 and 110,000 psi (515 and 760 MPa) are typical characteristics of the tubing. It is perfect for high-pressure, high-corrosion applications needing long-term dependability and material integrity because it retains mechanical stability over a broad temperature range.

| Nickel Alloy Specification | ASTM B163/ ASME SB163, ASTM B725/ ASME SB725 |

| Nickel Alloy Grades | UNSN08811, UNSN08825, UNSN08020, UNSN10276 |

| Nickel Alloy Type | SEAMLESS / WELDED / ERW / EFW / COLD DRAW / HOT FINISH / COLD FINISH |

| Nickel Alloy Outer Diameter Size | SEAMLESS – 1/2″ NB TO 18″ NB WELDED / ERW- 1″ NB TO 16″ NB EFW – 8″ NB TO 110″ NB |

| Nickel Alloy Wall Thickness | Schedule 10 To Schedule 160 (3 mm to 100 mm Thickness) |

| Nickel Alloy Length | 01 Meter to 12.5 Meters, Single Random Length, Double Random Length And Customize Size. |

| Nickel Alloy Ends | Plain Ends / Beveled Ends |

| Nickel Alloy Delivery Conditions | As Rolled, Formed, Stress Relieved, Annealed, Hardened, Tempered, Cold Draw, Bright Annealed |

| Nickel Alloy Coating | Electropolish, Mechanical Polish, Satin Finish, Passivated |

| Nickel Alloy Other Testing | Product Analysis, Transverse Tension Test, Flattening Test, Etching Test, Radiographic Examination, Stabilizing Heat Treatment, Intergranular Corrosion Test, Weld Decay Test, Magnetic Particle Detection, Grain Size Test, NACE 0175, Dual Grade, PWHT (POST WELD HEAT TREATMENT), Flare Test, Bend Test, Hardness Test, Tensile Test etc |

| Nickel Alloy Dimension | All Pipes Is Manufactured and Inspected / Tested to the Relevant standards including ASTM and ASME |

| Nickel Alloy Value Added Services | Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

| Nickel Alloy Packaging | Loose / Bundle / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector |

| Nickel Alloy Shipment & Transportation | By Road – Truck / Train, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |

| Nickel Alloy Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |

| Ni % | Cu % | Fe% | Mn % | C % | Si % | S % |

| 63.0 min | 28.0-34.0 | 2.50 max | 2.00 max | 0.30 max | 0.50 max | 0.024 max |

| Tensile Strength, Mpa | Yield Strength, MPa | Elongation, % | Hardness, HRB | |

| 483 min | 193 min | 35 min | – | +A |

| 586 min | 379 min | 15 min | 75 max | SR |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Nickel Alloy Instrumentation Tubing from Ojas Pipes and Tubes ensures high quality and durability, as this tubing offers excellent corrosion resistance and strength. Our commitment to exceptional service and reliable delivery guarantees customer satisfaction across various industrial applications. Our expertise in nickel alloy products ensures you receive a top-tier solution tailored to your needs.

Ojas Pipes and Tubes, one of the largest suppliers of Nickel Alloy Instrumentation Tubing in Kolkata, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Our extensive inventory and commitment to exceptional service make us the go-to choice for nickel alloy products in the region.

Yes, we offer custom sizes for Nickel Alloy Instrumentation Tubing to meet your specific requirements. Our team at Ojas Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@ojaspipesandtubes.co.in.

Instrumentation for Nickel Alloy Industries that require resistance to harsh media and harsh environments frequently use tubing. It is perfect for chemical injection systems, instrumentation lines, control systems, and hydraulic and pneumatic applications in nuclear power plants, refineries, offshore drilling, and oil and gas exploration. In corrosive conditions like seawater, acidic solutions, and high-temperature operations, these tubes function remarkably well. The aerospace, marine, and pharmaceutical industries also use nickel alloy tubing because of its dependability and durability. They are perfect for precision systems that are subjected to constant pressure and heat cycling because of their exceptional resistance to stress corrosion cracking.

©2024 Ojas Pipes and Tubes . All Rights Reserved.