Home > Stainless Steel > Stainless Steel Electropolished Pipes

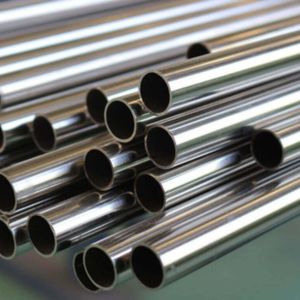

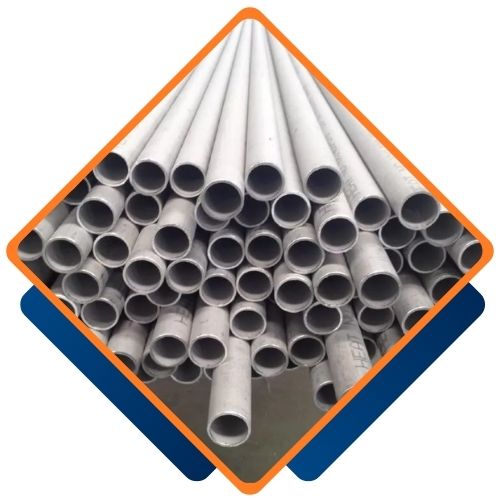

Delhi, India-based Ojas Pipes and Tubes, a reputable brand in the stainless steel sector, is a top producer and supplier of electropolished stainless steel pipes. These pipes are made with extreme precision and go through a sophisticated electropolishing process to produce incredibly smooth, contaminant-free surfaces that are perfect for critical and hygienic applications. Ojas is renowned for producing high-quality, corrosion-resistant goods that adhere to exacting industry requirements. The company offers customised solutions for semiconductor, food processing, pharmaceutical, and high-purity system applications in India and other international markets thanks to its cutting-edge infrastructure and knowledgeable staff.

Grades such as SS 304, 316, or 316L are commonly used to make stainless steel electropolished pipes. These grades have very low carbon content (≤0.03% for L grades), chromium (18–20%), nickel (8–14%), and molybdenum (2–3% in 316/316L). By eliminating surface contaminants and microscopic peaks, electropolishing improves the surface finish and resistance to corrosion. These pipes have an elongation of up to 40%, a yield strength of 170–310 MPa, and a tensile strength of 485–620 MPa. They are perfect for high-purity fluid transport systems because of their smooth, mirror-like internal surface, which lowers the risk of contamination, increases flow efficiency, and improves cleanability.

| Standard Specification | ASTM A312 / ASTM SA312 |

| ANSI Specification | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Available Shapes and Types | Square, Round, Rectangle, Hex, Hydraulic, Honed |

| Manufacturing Type | Fabricated, Welded, CDW, Seamless, 100% X Ray Welded, ERW |

| Pipe End Abbreviations | Treaded On End, Beveled One End, Treaded Both Ends, Bevel small end, Bevel large end, Beveled end, Plain Both Ends, Bevel one end, Plain One End, Bevel both ends |

| Various Technical Delivery Conditions Types | Annealed and Pickled, Cold Drawn, Polished, Bright Annealed |

| Different Surface Finish | 2B, No.4, No.1, No.8 Mirror Finish or custom Finish as per customer Requirements |

| Electropolished Pipes Schedule | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| We also provide | Cutting, Customer Tagging/ Marking, Beveling, Threading, Material testing, Grooving, Color Coding, Threading, Export Packaging, Polishing, Non Export Documentation, MTR’s Available, Machining, Destructive, Ultrasonic Testing, Destructive |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel Electropolished Pipes from Ojas Pipes and Tubes ensures high quality and durability, as these pipes offer excellent corrosion resistance and strength. Our commitment to exceptional service and reliable delivery guarantees customer satisfaction across various industrial applications. Our expertise in stainless steel products ensures you receive a top-tier solution tailored to your needs.

Ojas Pipes and Tubes, one of the largest suppliers of Stainless Steel Electropolished Pipes in Kolkata, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel Electropolished Pipes to meet your specific requirements. Our team at Ojas Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@ojaspipesandtubes.co.in.

Grades such as SS 304, 316, or 316L are commonly used to make stainless steel electropolished pipes. These grades have very low carbon content (≤0.03% for L grades), chromium (18–20%), nickel (8–14%), and molybdenum (2–3% in 316/316L). By eliminating surface contaminants and microscopic peaks, electropolishing improves the surface finish and resistance to corrosion. These pipes have an elongation of up to 40%, a yield strength of 170–310 MPa, and a tensile strength of 485–620 MPa. They are perfect for high-purity fluid transport systems because of their smooth, mirror-like internal surface, which lowers the risk of contamination, increases flow efficiency, and improves cleanability.

©2024 Ojas Pipes and Tubes . All Rights Reserved.