Home > Stainless Steel > Stainless Steel 316 and 316L Welded Tubing

Ojas Pipes and Tubes is a reliable manufacturer and supplier of superior Stainless Steel 316 and 316L Welded Tubing from Kolkata, India. With an emphasis on quality, innovation, and customer satisfaction, Ojas provides corrosion-resistant tubing solutions to meet the needs of various industries. Our offerings are manufactured from superior–quality raw materials and state-of-the-art welding methods to compete with international standards. Renowned for accuracy and reliability, we cater to industries like chemical processing, marine, food & beverages, and pharmaceuticals. Through on-time delivery and reasonable prices, Ojas Pipes and Tubes is an established go-to partner for stainless steel tubing solutions.

Stainless Steel 316 and 316L Welded Tubing consist of austenitic stainless steel that has chromium (16–18%), nickel (10–14%), and molybdenum (2–3%) for high corrosion resistance. The 316L grade contains less carbon, enhancing weldability and minimizing the potential for precipitation of carbides. Mechanical attributes comprise tensile strength of at least 515 MPa, yield strength of at least 205 MPa, and high elongation and toughness. Such features confer suitability to both 316 and 316L for high-pressure and corrosive environments, providing endurance and structural stability in demanding industrial applications.

Welded Tubes Size : 1 / 8″ NB – 24″ NB

Specifications : ASTM A/ASME SA213, A249, A269, A312, A358

Standard : ASTM, ASME and API

Length : Single Random, Double Random & Required Length

Outer Diameter : 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB

Thickness : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Schedule : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Types : Welded

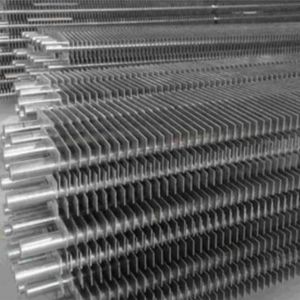

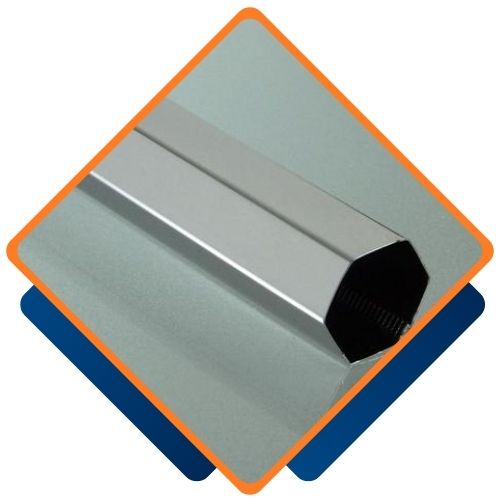

Form : Round Tubes, Square Tubes, Rectangular Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes

End : Plain End, Beveled End, Treaded

UNS | C Carbon | Mn | P | S | Si | Cr | Ni Nickel | Mo Molybdenum |

S31600 | 0.080 max | 2.00 max | 0.045 max | 0.030 max | 1.00 max | 16.0–18.0 | 10.0–14.0 | 2.00–3.00 |

S31603 | 0.030 max | 2.00 max | 0.045 max | 0.030 max | 1.00 max | 16.0–18.0 | 10.0–18.0 | 2.00–3.00 |

Yield Strength: | 30 ksi min |

Tensile Strength: | 75 ksi min |

Elongation (min 2″): | 35% |

Hardness (Rockwell B Scale): | 90 HRB max |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choose Stainless Steel 316 and 316L Welded Tubing from Ojas Pipes and Tubes for exceptional corrosion resistance, superior strength and excellent durability. Ideal for a variety of industrial applications it provides outstanding performance in harsh environments. With precision manufacturing and quality assurance, we ensure reliable and durable tubing solutions.

Ojas Pipes and Tubes is the largest supplier of Stainless Steel 316 and 316L Welded Tubing in Kolkata, India. Known for its high-quality products. We offer superior corrosion resistance, strength, and durability. Trusted by industries worldwide they provide reliable precision-engineered tubing for various applications and project needs.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

Yes, Ojas Pipes and Tubes offer large custom designs for Stainless Steel 316 and 316L Welded Tubing. With design, wall thickness and length. Their adjustable options ensure the tubing meets specific application requirements. This flexibility makes it more efficient and reliable for different industries and environments. For more details, contact us at sales@ojaspipesandtubes.co.in.

Stainless Steel 316 and 316L Welded Tubing has wide application in high corrosion-resistant and high-strength industries. Some of the typical uses are heat exchangers, chemical processing equipment, marine fittings, food and beverage processing equipment, drug manufacturing, and medical equipment. Their capacity to resist pitting, crevice corrosion, and stress corrosion cracking positions them perfectly in chloride-rich atmospheres like coastal or industrial locations. Besides, the even inner surface guarantees cleanliness and sanitation, essential for sanitary procedures. Because of their superior mechanical performance and adaptability, they are essential parts of piping systems, fluid transport, instrumentation, and structural systems.

©2024 Ojas Pipes and Tubes . All Rights Reserved.