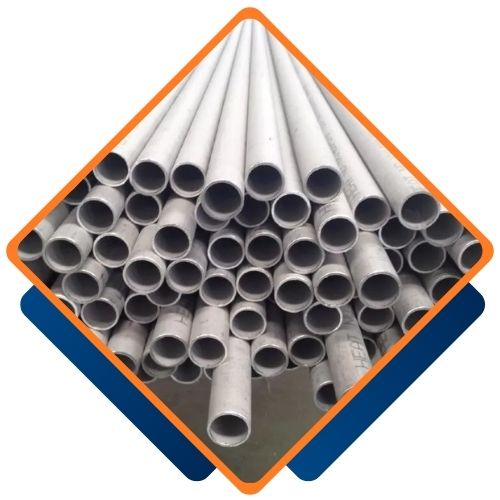

Premium aluminium instrumentation tubing for precise control and monitoring systems is available from Ojas Pipes and Tubes, a well-known manufacturer and supplier with headquarters in Delhi, India. This tubing is well-known for its high strength-to-weight ratio, corrosion resistance, and lightweight nature, making it perfect for industries that need precise fluid and gas gearbox. Ojas is manufactured in accordance with strict quality standards, guaranteeing excellent performance under a range of pressure and temperature conditions, smooth internal surfaces, and consistent dimensional accuracy. The oil and gas, chemical, petrochemical, and aerospace industries rely on our aluminium instrumentation tubing because of its dependability, toughness, and simplicity of fabrication and installation.

Instrumentation made of aluminium In order to increase strength, weldability, and corrosion resistance, tubing is usually made from alloys like 6061 or 5083, which contain 90%+ aluminium and additional silicon, magnesium, and trace elements. Depending on the alloy and temper, mechanical properties include tensile strength between 240 and 310 MPa, yield strength between 95 and 270 MPa, and elongation between 10 and 17%. The tubing has outstanding dimensional stability, is lightweight, and is non-magnetic. Because of these qualities, it is perfect for high-precision, pressure-sensitive settings where reliability and resistance to corrosion are crucial.

Standards : ASTM B345, B241, B429 / ASME SB345, SB241, SB429

Standard : AMS QQ-A-200/8, AMS QQ-A-200/9, AMS 4160/4161/4172

Size : 8 (1-1/2″ / 1.900″)

Outer Diameter : 1″ through 16″

Length : Double Random, Single Random, Cut Length

Thickness : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

End : Plain End, Beveled End, Threaded

ASTM B429 / ASME SB429 – Standard Specification for Aluminum-Alloy Extruded Structural Tube and Tube

EN AW-AlMg1SiCu – Standard Specification for Aluminum and Aluminum-Alloy Round Tube

ISO AlMg1SiCu – Standard Specification for Aluminum and Aluminum-Alloy Cold / Hot Rolled Tubing

| Alloy | Fe | Si | Mg | Mn | Cu | Zn | Ti | Cr | Others | AI |

| 1100 (min) | 0.35 | 0.25 | 0.01 | 0.01 | 0.05 | 0.01 | 0.020 | Trace | 0.05 (each) | 99.60% |

| 1100 (max) | 0.50 | 0.35 | 0.03 | 0.05 | 0.20 | 0.05 | 0.030 | Trace | 0.15 (total) | remainder |

| 5083 | 0.40 max | 0.40 max | 4.0 / 4.90 | 0.40 / 1.0 | 0.10 max | 0.25 max | 0.15 max | 0.05 / 0.25 | 0.05 max | Bal |

| 6061 | 0.7 | 0.4-0.8 | 0.8-1.2 | 0.15 | 0.15-0.4 | 0.25 | 0.15 | 0.15-0.35 | 0.005/0.15 | Remainder |

| 6068 | 0.50 max | 0.7 – 1.3 | 0.06-1.20 | 0.40-1.00 | 0.10 max | 0.20 max | 0.10 max | 0.25 max | 0.05 max | Bal |

| 7075 min | 2.10 | 1.20 | 5.10 | 0.18 | ||||||

| 7075 max | 0.50 | 0.40 | 2.90 | 0.30 | 2.00 | 6.10 | 0.20 | 0.28 | 0.05 |

| Alloy | Temper | UTS(Mpa) | % Elongation | Tensile Strength | Hardness Brinell | Proof Stress | Yield Strength (PSI) | Shear Strength (PSI) | Brinell Hardness | |||

| Min | Max | 0.5 mm -0.8 mm | 0.81 mm – 1.30 mm | 1.30 mm – above | ||||||||

| 1100 | O | 75 | 110 | 20 | 25 | 29 | ||||||

| H12 | 95 | 130 | 5 | 6 | 7 | |||||||

| H14 | 110 | 145 | 3 | 4 | 5 | |||||||

| H16 | 130 | 165 | 2 | 3 | 4 | |||||||

| H18 | 150 | — | 2 | 2 | 3 | |||||||

| 5083 | 12 Min % | 275 – 350 MPa | 75 HB | 125 Min MPa | ||||||||

| 6061 | – | 45,000 | 12 | 40,000 | 31,000 | 95 | ||||||

| 6082 | 8 | 295 | 95 | – | 240 | – | – | |||||

| 7075 T6, T651 | 11 | 83-572 | 73- 503 | 150 | ||||||||

| 7075 T73, T7351 | 13 | 73-503 | 63-434 | NA | ||||||||

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Aluminium Instrumentation Tubing from Ojas Pipes and Tubes ensures superior quality and performance. Ojas Pipes and Tubes offer tubing manufactured with precision to meet the highest industry standards, providing excellent corrosion resistance, durability, and lightweight properties ideal for critical instrumentation applications. Their aluminium tubing is crafted to ensure seamless finish and enhanced reliability in demanding environments. Additionally, Brydon offers a wide range of custom sizes and prompt delivery, ensuring clients receive the best solutions tailored to their specific needs, backed by excellent customer service and technical expertise.

Ojas Pipes and Tubes, one of the largest suppliers of Aluminium Instrumentation Tubing in Kolkata, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Aluminium Instrumentation Tubing to meet your specific requirements. Our team at Ojas Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@ojaspipesandtubes.co.in.

| Grade | UNS | USA | Japan | France | ISO | WNR | EN | DIN | ISO | BS (OLD) |

| 1100 | A91100 | AA1100 | JIS A1100P | NF 1100 | Al 99.0 Cu. | – | – | – | – | – |

| 6082 | A96082 | AA6082 | – | – | – | 3.2315 | AW-6082 | AlMgSi1 | AlSi1MgMn | HE30 |

| 5083 | A95083 | 5083 | – | – | AlMg4,5Mn0,7 | 3.3547 | AW-AlMg4,5Mn0,7 | AlMg4,5Mn | – | – |

| 6061 | A96061 | AA6061 | – | – | – | 3.3211 | AW-AlMg1SiCu EN AW-6061 | AlMgSiCu | AlMg1SiCu | HE20 |

| 7075 | A97075 | 7075 | 3.4365 | ENAW-AlZn5.5MgCu EN AW-7075 | AlZnMgCu1.5 | AlZn6MgCu | 7075 L95 L96, V95 |

Instrumentation made of aluminium Tubing is widely used for controlling pressure systems and transmitting instrumentation signals in the petrochemical, chemical processing, and oil and gas exploration industries. It is perfect for cleanroom settings, analytical equipment, and laboratory setups due to its non-reactivity and resistance to corrosion. Fuel lines, hydraulic controls, and fluid distribution systems are among its applications in aerospace and defence. Additionally, it is used in food processing, pharmaceutical facilities, and marine equipment where corrosion resistance and cleanliness are essential. High-integrity, compact, and intricate piping layouts can benefit from the tubing’s lightweight design, easy bendability, and precise tolerances.

©2024 Ojas Pipes and Tubes . All Rights Reserved.