Home > Duplex Steel > Duplex Steel Seamless Tubing

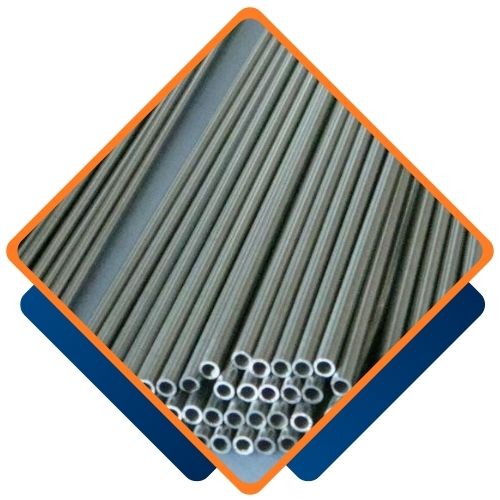

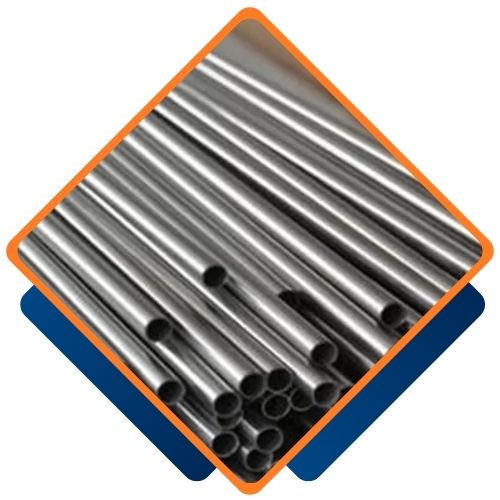

Duplex Steel Seamless Tubing is made up of about 22% Chromium, 5–6.5% Nickel, 3% Molybdenum, and the rest is Iron, with small amounts of Nitrogen and Manganese. This carefully balanced composition creates a dual-phase microstructure of ferrite and austenite, providing outstanding strength and corrosion resistance. Typical mechanical properties feature a tensile strength ranging from 620 to 880 MPa, yield strength between 450 and 550 MPa, and a minimum elongation of 25%. The combination of high strength and excellent resistance to chloride-induced stress corrosion cracking makes Duplex tubing perfect for challenging environments.

Duplex Steel Seamless Tubing is typically composed of 22% chromium, 5-6% nickel, 3% molybdenum, and nitrogen, with the balance being iron. This composition provides excellent corrosion resistance, especially against pitting, crevice corrosion, and stress corrosion cracking. The mechanical properties include a tensile strength of 620 MPa, yield strength of 450 MPa, and elongation of 25%. Advantages include high strength, resistance to harsh environments, and reduced wall thickness, making it a cost-effective solution for industries like oil and gas, chemical processing, and marine applications.

tube Range : 1 / 2″ NB – 8″ NB

Outer Diameter : 6.0-630mm

Wall Thickness : 0.3mm – 50 mm

Schedules : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Length : Single Random, Double Random & Required Length

Specifications : ASTM A789 / ASME SA789

Types : Seamless

| Duplex | Seamless |

|---|---|

| Ni | 4.50 – 6.50 |

| Fe | 63.72 min |

| Cr | 22.0 – 23.0 |

| C | 0.030 max |

| Si | 1.00 max |

| Mn | 2.00 max |

| P | 0.030 max |

| S | 0.020 max |

| N | 0.14 – 0.20 |

| Duplex Steel | Seamless |

| Density (g/cm 3) | 7.805 |

| Density (lb/in 3) | 0.285 |

| Melting Point (°C) | 1420 – 1465 |

| Melting Point (°F) | 2588 – 2669; |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

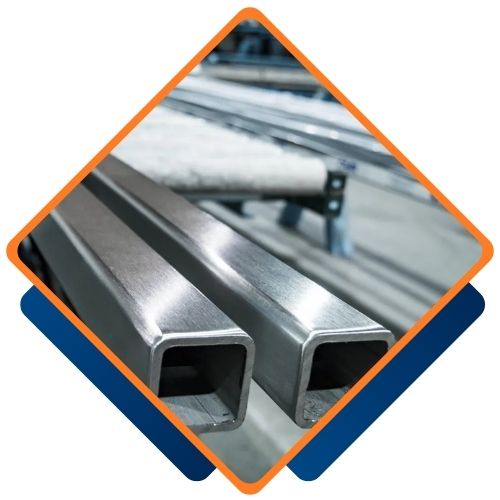

Choosing Duplex Steel Seamless Tubes from Ojas Pipes and Tubes ensures superior quality and durability, offering outstanding corrosion resistance and high strength. Our dedication to delivering exceptional service and reliable products guarantees customer satisfaction across a wide range of industrial applications. With our expertise in Duplex steel solutions, you can trust us to provide a top-tier, customized piping solution that meets your specific requirements.

Ojas Pipes and Tubes, one of the largest suppliers of Duplex Steel Seamless Tubing in the Kolkatas, India. Offers a wide range of high-quality pipes and tubes designed for various industrial applications. Their extensive inventory and dedication to exceptional service make them a trusted choice for Duplex steel products in the region, delivering reliable solutions to meet diverse project requirements.

Yes, we provide custom sizes for Duplex Steel Seamless Tubes to meet your specific requirements. At Ojas Pipes and Tubes, our team is dedicated to delivering tailored solutions for all your piping and tubing needs. For more information, please contact us at sales@ojaspipesandtubes.co.in.

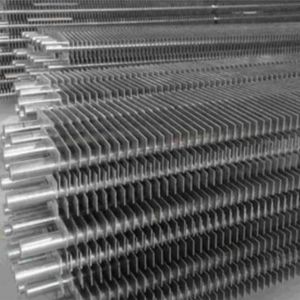

Duplex Steel Seamless Tubing finds its place in various demanding industries where high strength and corrosion resistance are crucial. You’ll often see it used in heat exchangers, desalination plants, oil and gas processing, and systems for chemical storage and transport. It’s particularly well-suited for offshore platforms, pressure vessels, and the pulp and paper industries, as well as marine environments where chloride-induced corrosion poses a risk. Thanks to its dual-phase structure, this tubing offers enhanced resistance to stress corrosion cracking, erosion, and fatigue. With its remarkable mechanical performance and long service life, Duplex seamless tubing is a reliable choice for many applications.

©2024 Ojas Pipes and Tubes . All Rights Reserved.