Home > Nickel Alloy > Nickel Alloy Seamless Tubing

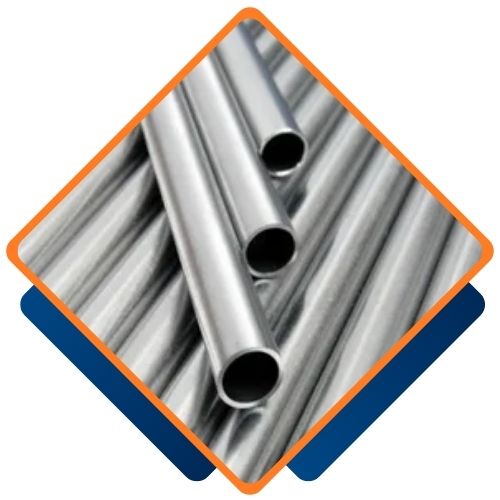

Ojas Pipes and Tubes stands out as a reliable manufacturer and supplier of Nickel Alloy Seamless Tubing right in Kolkata, India. We specialize in delivering precision-engineered tubing solutions that can handle the toughest environments. Our seamless tubes come in a variety of nickel-based alloys, including Nickel 200/201, Alloy 400, Alloy 600, Alloy 625, and Alloy 825, all crafted to meet international standards like ASTM B163, B167, and B423. Built to resist corrosion, heat, and pressure, our seamless tubing is perfect for critical applications in sectors like chemical processing, power generation, aerospace, and marine industries. At Ojas, we prioritize dimensional accuracy, strength, and long-lasting performance.

Nickel Alloy Seamless Tubing generally consists of Nickel (≥65%) as the primary element, with different amounts of Chromium, Molybdenum, Copper, Iron, and Titanium based on the specific grade. For instance, Alloy 625 contains about Ni (~58%), Cr (20–23%), and Mo (8–10%), which gives it exceptional corrosion resistance. The mechanical properties include a tensile strength ranging from 550 to 950 MPa, yield strength between 200 and 600 MPa, and elongation of up to 45%. The seamless design guarantees consistent strength, a superior surface finish, and outstanding performance even under high-pressure and high-temperature conditions.

| Nickel Tubing Standards | ASTM B163/ ASME SB163, ASTM B725/ ASME SB725 |

|---|---|

| Nickel Seamless Tube Size | 3.35 mm OD To 101.6 mm OD |

| Marking | All Nickel Tubing are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Nickel Steel Tubing Length | Single Random, Double Random, Standard & Cut length Tube |

| Nickel Steel Tubing Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| Specialize in | Nickel Capillary Tube & Other Odd Size Pure Nickel Alloy Heat Exchanger & Condenser Tube |

| Form | ‘U’ bent, Hollow, Hydraulic, LSAW, Boiler, Straight Tube, Tube Coil, Round, Rectangular, Square Etc |

| Types of Pure Nickel Tubing | Seamless, ERW, EFW, Welded, Fabricated Tube / Tubing |

| Nickel Steel Tube wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| Pure Nickel Tube End | Plain End, Beveled End, Treaded Tube |

| Nickel Welded Tube Size | 6.35 mm OD To 152 mm OD |

| Pure Nickel Alloy Tubing Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Application & uses of Nickel seamless tube | Oil Tube, Gas Tube, Fluid Tube, Boiler Tube, Heat exchanger Tube, |

| Test Certificate | Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab. Under Third Party Inspection |

| Nickel 200 | Ni | C | Mo | Mn | Si | Fe | P | S | Cu | Cr |

| 99.0 Min | 0.15 Max | – | 0.35 Max | 0.1 Max | 0.4 Max | – | 0.01 Max | 0.25 Max | – | |

| Nickel 201 | Ni | C | Mo | Mn | Si | Fe | P | S | Cu | Cr |

| Balance | 0.15 Max | – | 0.35 Max | 0.35 Max | 0.40 Max | – | 0.01 Max | 0.25 Max | – |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | |

| 8.9 G/Cm3 | 1446 °C (2635 °F) | Psi – 21500 , MPa – 148 | Psi – 67000 , MPa – 462 | 45 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Nickel Alloy Seamless Tubing from Ojas Pipes and Tubes ensures high quality and durability, as this tubing offers excellent corrosion resistance and strength. Our commitment to exceptional service and reliable delivery guarantees customer satisfaction across various industrial applications. Our expertise in nickel alloy products ensures you receive a top-tier solution tailored to your needs.

Ojas Pipes and Tubes, one of the largest suppliers of Nickel Alloy Seamless Tubing in Kolkata, India, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Our extensive inventory and commitment to exceptional service make us the go-to choice for nickel alloy products in the region.

| Wall Thickness (WT) | Nickel Tube Size Chart ( O.D.) |

|---|---|

| .010 | 1/16″ , 1/8″ , 3/16″ |

| .020 | 1/16″ , 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ |

| .012 | 1/8″ |

| .016 | 1/8″ , 3/16″ |

| .028 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 3/4″ , 1″ , 1 1/2″ , 2″ |

| .035 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 7/16″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .049 | 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/8″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .065 | 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 3/4″ , 2″ , 2 1/2″ , 3″ |

| .083 | 1/4″ , 3/8″ , 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 7/8″ , 2″ , 2 1/2″ ,3″ |

| .095 | 1/2″ , 5/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .109 | 1/2″ , 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .120 | 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 2 1/4″ , 2 1/2″ , 3″ |

| .125 | 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 3″ , 3 1/4″ |

| .134 | 1″ |

| .250 | 3″ |

| .375 | 3 1/2″ |

Yes, we offer custom sizes for Nickel Alloy Seamless Tubing to meet your specific requirements. Our team at Ojas Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@ojaspipesandtubes.co.in.

Nickel Alloy Seamless Tubing finds extensive use in various fields such as chemical processing, pharmaceuticals, marine applications, aerospace systems, and nuclear power plants. These tubes are perfect for heat exchangers, boiler feed lines, reactor vessels, desalination systems, and evaporators, where resistance to corrosion and thermal stress is crucial. In the oil and gas sector, they are utilized in downhole equipment and control lines. Nickel 200/201 is particularly suited for caustic media, while Alloys 625 and 825 are preferred for acidic, oxidizing, and chloride-rich environments. Their seamless construction ensures leak-proof integrity and high reliability in demanding, high-stress situations.

©2024 Ojas Pipes and Tubes . All Rights Reserved.